We are providing a wide range of services in bridge construction including:

1. Post-tensioning works for bridge:

Post-tensioning for bridge girder segment errection

Post-tensioning for bridge girder segment errection

Post-tensioned (PT) components indispensable in bridge construction. Longer spans can be achieved due to prestress, which can also be used to counteract deflections.

Post-tensioned components use high-strength tensioned steel strands to compress the slabs, keeping the majority of the concrete in compression. This gives a very efficient structure which minimises material usages and decreases the economic span range when compared to reinforced concrete.

Benefits: Fire resistance, Cost, Speed, Reduced material use, Sound control, Robustness, Thermal mass, Minimal deliveries

2. Special formwork system and gantry

Climbing formwork is a special type formwork for vertical concrete structures that rises with the building process such as bridge piers and cable bridge pylons. While relatively complicated and costly, it can be an effective solution for buildings that are either very repetitive in form or that require a seamless wall structure.

Climbform for cable bridge pylon

Climbform for cable bridge pylon

Various types of climbing formwork are available to match every client’s need, which are either relocated from time to time, or can even move on their own (usually on hydraulic jacks, required for self-climbing and gliding formworks).

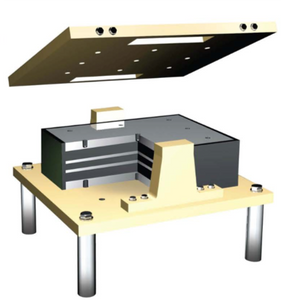

The Form traveller system is acclaimed for enhancing the cost-effectiveness of bridge projects worldwide. The system is lightweight, versatile, easy to assemble and operate, rolling forward on rails, the system can be reset quickly and easily.

Formtraveller

Formtraveller

The Form traveller is used for free cantilever construction of post-tensioned box girder – and cable-stayed concrete bridges. The Form traveller may be adapted to suite almost any cross-section, and is easily adjustable during operation to variations in segment length, section height, web thickness, and deck width.

Other tailor-made solutions for specific requirements are made upon client’s inquiries.

3. Expansion Joint and Bearing

Bridge expansion joints are designed to allow for continuous traffic between structures while accommodating movement, shrinkage, and temperature variations on reinforced and prestressed concrete, composite, and steel structures. They stop the bridge from bending out of place in extreme conditions, and also allow enough vertical movement to permit bearing replacement without the need to dismantle the bridge expansion joint. There are various types, which can accommodate movement from 30 to 1,000 millimetres. They include joints for small movement (EMSEAL BEJS, XJS, JEP, WR, WOSd, and Granor AC-AR), medium movement (ETIC EJ, Wd), and large movement (WP, ETIC EJF/Granor SFEJ).

Bridge expansion Joint

Bridge expansion Joint

A bridge bearing is a component of a bridge which typically provides a resting surface between bridge piers and the bridge deck. The purpose of a bearing is to allow controlled movement and thereby reduce the stresses involved. Movement could be thermal expansion or contraction, or movement from other sources such as seismic activity. There are several different types of bridge bearings which are used depending on a number of different factors.

Bridge bearing

Bridge bearing

4. Stay cable system

A cable-stayed bridge has one or more towers (or pylons), from which cables support the bridge deck. A distinctive feature are the cables or stays, which run directly from the tower to the deck, normally forming a fan-like pattern or a series of parallel lines. This is in contrast to the modern suspension bridge, where the cables supporting the deck are suspended vertically from the main cable, anchored at both ends of the bridge and running between the towers. The cable-stayed bridge is optimal for spans longer than cantilever bridges and shorter than suspension bridges. This is the range where cantilever bridges would rapidly grow heavier if the span were lengthened, while suspension bridge cabling would not be more economical if the span were shortened.

Stay cable bridge